When searching for the optimal 6 gauge wire connectors, it is crucial to consider factors such as type, durability, and specific use cases to ensure dependable and safe electrical connections. Whether you’re working on an automotive project or a home wiring system, selecting the right connector can greatly influence performance and safety. This guide will explore the essential aspects of 6 gauge wire connectors, including their varieties, key features, and installation techniques.

Content

Understanding 6 Gauge Wire Connectors

Definition and Purpose

6 gauge wire connectors are integral components used to join or splice 6 gauge wires securely in various electrical setups. They ensure stable electrical connections, which are vital for the safe operation of electrical systems. Proper use of these connectors maintains the current flow and integrity of the wire connections.

Types of 6 Gauge Wire Connectors

Crimp Connectors for 6 Gauge Wires

6 gauge crimp connectors are favored for their straightforward installation and reliable performance. These connectors work by compressing around the wire, creating a solid connection. They are especially useful in tight spaces where a secure connection is essential.

| Type | Features | Best For |

| Crimp Connectors | Easy installation, secure connection | Tight spaces, quick repairs |

| Insulated Crimp Connectors | Added protection against short circuits | General wiring, protection from moisture |

Wire Splices for 6 Gauge Wires

6 gauge wire splices serve to join two wires, making them suitable for extending or repairing wire connections. These versatile connectors are applicable in a range of electrical projects.

| Type | Features | Best For |

| Butt Splice Connectors | Joins two wires end-to-end | Extensions, repairs |

| Tube Splice Connectors | Provides a strong, long-lasting connection | Permanent connections, heavy-duty use |

Terminal Connectors for 6 Gauge Wires

6 gauge wire connector terminals are designed to attach wires to components like switches or terminals, ensuring a secure and stable connection. These are particularly useful in applications requiring easily accessible or removable connections.

| Type | Features | Best For |

| Ring Terminals | Provides a secure connection with a bolt | Automotive, machinery |

| Spade Terminals | Easy to connect and disconnect | Appliances, electronics |

Features to Look for in 6 Gauge Wire Connectors

Heavy Duty and Durability

Selecting heavy-duty 6 gauge wire connectors is essential for handling the demands of your electrical system. These connectors are engineered to withstand higher currents and are crafted from durable materials that resist wear and tear.

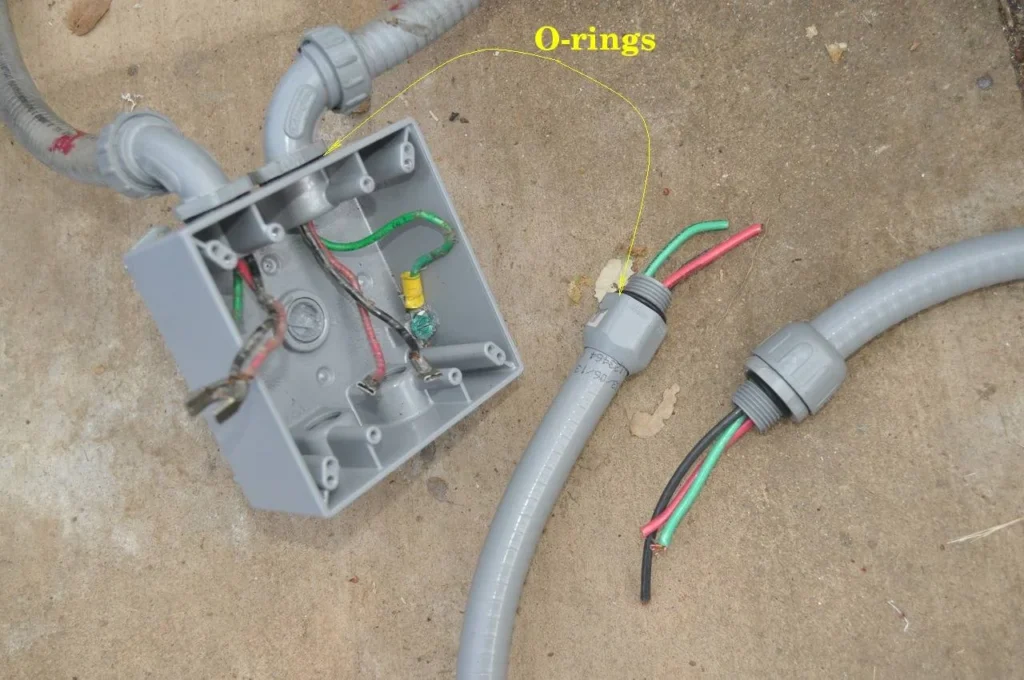

Waterproof Connectors

Waterproof 6 gauge wire connectors are designed to prevent moisture ingress, which can lead to corrosion and connector failure. These connectors are ideal for use in outdoor environments or areas exposed to water.

Automotive Use

For automotive applications, 6 gauge wire connectors for automotive are specifically designed to endure vibrations, heat, and other challenging conditions found in vehicles. Choosing appropriate connectors ensures reliable and long-lasting performance.

Selecting the Best 6 Gauge Wire Connectors

Top Brands and Products

When choosing 6 gauge wire connectors, consider reputable brands known for high-quality products. Comparing features, user reviews, and pricing will help you find the most suitable connectors for your requirements.

| Brand | Product | Features | Price Range |

| Brand A | Heavy Duty Connectors | High durability, waterproof options | $$ |

| Brand B | Automotive Connectors Kit | Includes various types, high performance | $$$ |

Connector Kits

6 gauge wire connector kits offer a convenient solution for those needing a range of connectors for different applications. Kits typically include crimp connectors, splices, and terminals, making them versatile for various projects.

Installation Tips for 6 Gauge Wire Connectors

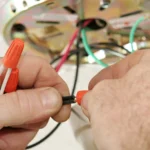

Proper Crimping Techniques

To ensure a secure connection with 6 gauge crimp connectors, use the correct crimping tool and technique. Adhere to the manufacturer’s instructions to achieve optimal results and ensure the connector is fully compressed around the wire.

Splicing and Terminating

When working with 6 gauge wire splices, follow these steps for best practices:

- Strip the insulation from the wires.

- Insert the wires into the splice connector.

- Employ a crimping tool to secure the splice.

- Confirm a firm connection by testing the splice.

Maintenance and Troubleshooting

Common Issues and Solutions

Frequent issues with 6 gauge electrical wire connectors include loose connections or corrosion. Regular inspection and maintenance are crucial to preventing these problems. For troubleshooting, verify proper installation and replace any damaged connectors as needed.

Conclusion

Selecting the right 6 gauge wire connectors is crucial for ensuring reliable and safe electrical connections. Understanding the different types, features, and installation techniques will enable you to make informed decisions and achieve optimal performance in your electrical projects.

Elena Mohr is a dedicated home blogger who has been blogging for over six years. She covers everything home related. Elena also loves writing posts about her travels to Europe with her husband and two children.

![Why Spray Foam Insulation Vaughan Homes Need: An Expert Guide [2025] Spray Foam Insulation](https://starthomeimprovement.com/wp-content/uploads/2025/09/image-150x150.png)